Professional brand building, service creates the future

Precise spring customization gives you the right spring price and high-quality service

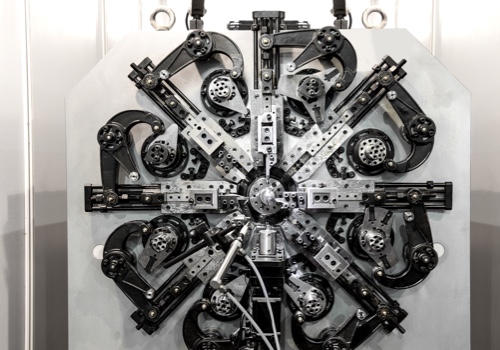

According to your needs, we can customize the spring size, specification and quantity in 2 hours for quotation, 36 hours for sample delivery, and expedited on the same day

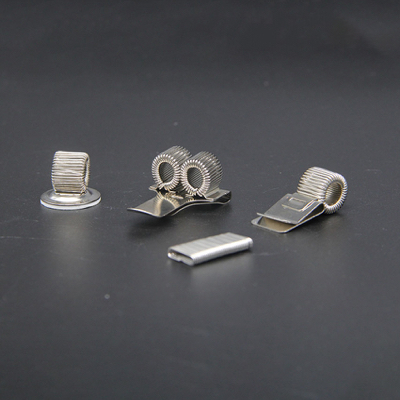

Provide you with a variety of fast CNC precision spring processing customized pictures related price specifications

Dongguan Tianzhu Industrial Co., Ltd.

Complete the project

Plant area

Tension spring custom manufacturer

Compression spring custom manufacturer

Compression springs (compression springs) are helical springs under pressure. Most of the materials used are circular in cross-section, and they are also rolled in rectangular and multi-strand steel coils. The springs are generally of equal pitch. The shapes of the compression springs are: Cylindrical, conical, convex and concave shapes, and a small amount of non-circular shapes, etc., there is a certain gap between the coils of the compression spring, and the spring shrinks and deforms when subjected to an external load to store deformation energy. Compression springs are generally coiled metal wires with equal pitches and fixed wire diameters. Compression springs use multiple open coils to provide resistance to external load (such as gravity pressing down on a wheel, or body pressing on a mattress). That is, they push back to resist external pressure. Compression springs are generally coiled metal wires with equal pitches and fixed wire diameters.

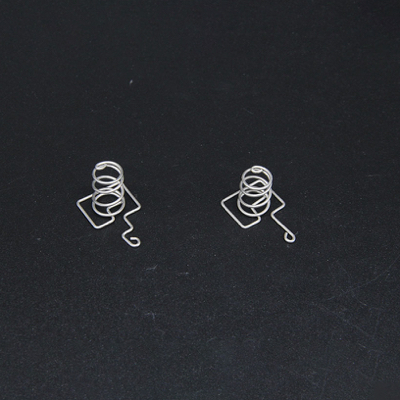

Torsion spring custom manufacturer

Torsion Spring is one of the more complicated design principles in all spring categories, and the changes in styles are also quite lively, so the theory involved in the design is also the most cumbersome. The ends of the torsion spring are fixed to other components, and when the other components rotate around the center of the spring, the spring pulls them back to their original positions, generating torque or rotational force. The torsion spring can store and release angular energy or rotate the arm around the central axis of the spring body to statically fix a device. This type of spring is usually dense, but there is a pitch between the coils to reduce friction. They generate resistance to rotation or external forces of rotation.

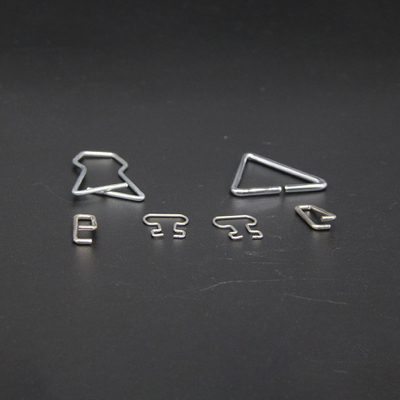

Special-shaped spring custom manufacturers